Smart Lockout

Lukko Safety offers a complete IoT-based security lock management platform, providing smart, reliable, and advanced safety solutions. We are your trusted Internet of Things–enabled active security provider.

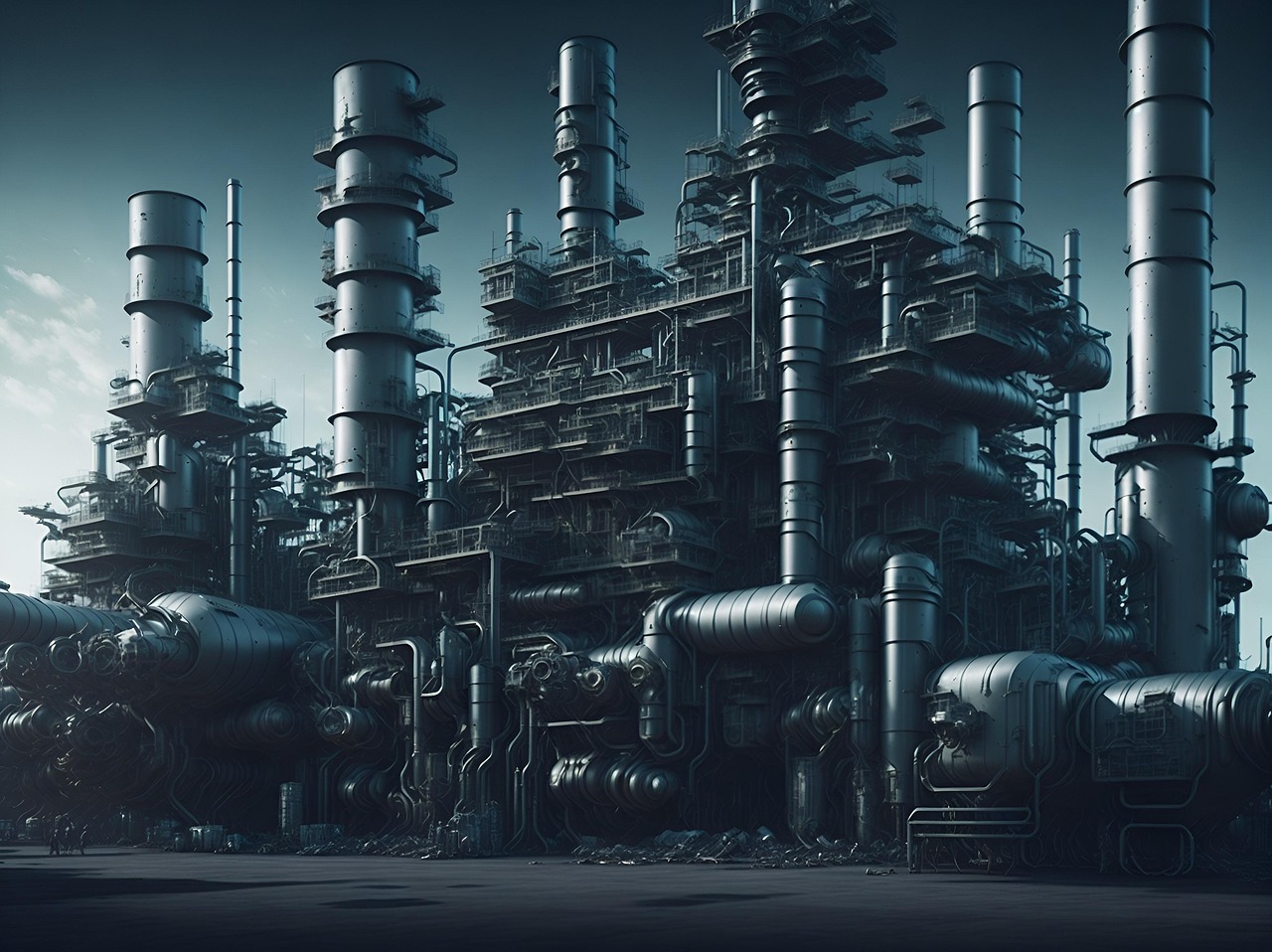

Industry status

Lukko Safety’s smart lockout solutions bring intelligence, reliability and simplicity to hazardous energy control, helping industries move from basic compliance to a more proactive safety culture.

Built on its expertise in Lockout Tagout hardware, the smart range uses compact, adjustable devices that enable maintenance teams to isolate electrical, mechanical and valve energy points quickly and correctly, even on complex machinery. Standardized, durable designs reduce human error and unplanned downtime, while clear visual indication and robust locking mechanisms ensure only authorized personnel can re-energize equipment after work is complete.

With CE-compliant construction and alignment to OSHA-style practices, Lukko Safety’s smart lockout portfolio supports global audit readiness and helps industrial plants create a more accountable and efficient maintenance environment.

Industry Management of pain point analysis

Industrial safety management faces key pain points like inconsistent employee adherence to LOTO protocols, leading to frequent hazardous energy incidents and compliance gaps. Lukko Safety addresses these through smart lockout analysis, enabling real-time audits, accountability tracking, and data-driven training to reduce downtime and boost safety culture.

Lock Management

Lukko Safety's lock management ensures secure, traceable control of LOTO padlocks and devices, preventing unauthorized access and lost keys across multi-shift operations. Smart features like keyed-alike sets, color-coding, and numbered tagging streamline inventory audits, reduce mix-ups, and maintain compliance during high-volume maintenance tasks.

Lock Point Identification

Lukko Safety's Lock Point Identification simplifies hazardous energy source mapping with visual tags, labels, and standardized diagrams for accurate isolation points on machinery and panels. This reduces errors in complex setups by enabling quick verification, team training, and audit-ready documentation during maintenance workflows

Lock Status Confirmation

Lukko Safety's Lock Status Confirmation uses visual indicators, tamper-evident tags, and multi-lock hasps to verify all energy isolation points are securely locked before maintenance begins. This ensures zero surprises during verification rounds, minimizing re-energization risks and supporting clear handoff between shifts for full compliance.

Master Schedule

Lukko Safety's Master Schedule coordinates LOTO activities across teams with centralized planning boards, digital checklists, and visual timelines for maintenance shutdowns. This eliminates scheduling conflicts, ensures complete lockout coverage, and facilitates real-time updates for efficient resource allocation and compliance tracking.

Repair Order Query

Lukko Safety's Repair Order Query streamlines maintenance tracking with integrated LOTO documentation, linking lock status to work orders for real-time visibility. This ensures quick retrieval of repair histories, compliance proofs, and authorization logs, reducing delays and enhancing audit readiness during inspections.

Personnel Qualifications

Lukko Safety's Personnel Qualifications verify authorized workers through LOTO training certifications, ID-linked tags, and competency checklists before issuing locks or access. This prevents unqualified personnel from maintenance tasks, ensures skill-matched assignments, and maintains detailed records for regulatory audits and incident investigations.

Technical Breakthrough

Through protocol docking, visual management, and hardware customization, Lukko Safety realizes its advanced smart Lockout Tagout (LOTO) platform for seamless hazardous energy isolation across industrial environments.

This IoT-enabled system integrates real-time lock status tracking, tamper-evident tags, adjustable multi-point devices, and centralized dashboards to streamline maintenance workflows, minimize human error, and ensure OSHA-aligned compliance.

By connecting physical LOTO hardware with digital verification tools, it empowers EHS teams with instant audits, personnel qualification checks, and repair order queries, transforming safety from reactive to predictive.

Why Choose Us

Visualization

Lukko Safety’s visualization tools provide clear diagrams and real-time dashboards for energy source mapping, enabling instant identification of lock points and status across complex machinery. This reduces errors during audits and training, ensuring teams visualize isolation procedures accurately for enhanced compliance.

Work Order

Integrated work order management links LOTO procedures directly to repair tasks, tracking authorization, timelines, and completion with digital checklists. Maintenance teams access historical data and notifications, minimizing downtime while maintaining OSHA-aligned documentation.

LOTO Management

Advanced LOTO management offers tamper-evident tags, multi-lock hasps, and protocol docking for secure, traceable energy isolation across shifts. Centralized platforms enforce standardized procedures, personnel qualifications, and verification to prevent unauthorized re-energization.

Resource Allocation

Efficient resource allocation optimizes lock inventory, keyed-alike sets, and kits through visual planning boards and real-time availability tracking. This eliminates shortages during peak maintenance, supports multi-site operations, and boosts productivity without safety compromises.

Event Notification

Automated event notifications alert teams to lock status changes, shutdown schedules, and compliance alerts via integrated dashboards. Ensures seamless communication for shift handoffs, incident reporting, and regulatory updates, fostering a proactive safety culture.