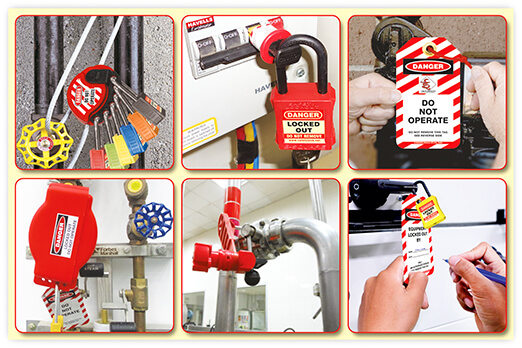

Lockout/Tagout (LOTO) procedures are a critical aspect of workplace safety, ensuring that machinery and equipment are properly shut down and cannot be restarted until maintenance or repair work is complete. While locks are the cornerstone of these procedures, a range of essential LOTO accessories can significantly enhance safety. At Lukkosafety.com, we provide comprehensive solutions, including products from the best LOTO tags manufacturer in India, to ensure your workplace remains secure and compliant with safety standards.

1. LOTO Tags: Communicating Vital Information

LOTO tags are indispensable in any lockout/tagout system. They provide crucial information about the lockout, including the person responsible, the date, and the reason for the lockout. Using high-quality tags from the best LOTO tags manufacturer in India ensures durability and visibility, even in harsh industrial environments. Look for tags that are tear-resistant, water-resistant, and easy to write on.

Key Features to Consider:

- Durability: Tear and water-resistant materials.

- Visibility: Bright colors and clear, legible text.

- Customization: Space for detailed information.

2. Lockout Hasps: Securing Multiple Workers

Lockout hasps allow multiple workers to lock out a single energy source. Each worker attaches their lock to the hasp, ensuring that the equipment cannot be re-energized until all locks are removed. This is particularly useful in team maintenance situations where multiple employees need to work on the same piece of equipment.

Key Features to Consider:

- Number of Lock Holes: Choose hasps with enough holes to accommodate all workers involved.

- Material: Durable materials like steel or aluminum for robustness.

- Size: Ensure the hasp fits the specific machinery or equipment.

3. Valve Lockouts: Controlling Flow Safely

Valve lockouts are essential for isolating the flow of liquids and gases during maintenance. These devices are designed to fit various types of valves, including ball, gate, and butterfly valves, ensuring complete lockout of the energy source.

Key Features to Consider:

- Compatibility: Ensure the lockout device fits the specific type of valve.

- Durability: Resistant to chemicals and extreme temperatures.

- Ease of Use: Simple to install and remove.

4. Circuit Breaker Lockouts: Electrical Safety First

Circuit breaker lockouts are designed to fit most circuit breaker types, preventing accidental re-energization. These devices are crucial for electrical maintenance and ensure that the electrical panel remains inaccessible during repairs.

Key Features to Consider:

- Versatility: Compatibility with various breaker sizes and types.

- Durability: Made from robust materials to withstand electrical environments.

- Visibility: Bright colors to signal that the breaker is locked out.

5. Plug Lockouts: Securing Electrical Connections

Plug lockouts are used to secure the plugs of electrical devices, preventing them from being plugged into an outlet. These are particularly useful for portable equipment and tools.

Key Features to Consider:

- Size and Compatibility: Ensure the lockout device fits the plug size.

- Material: Durable and non-conductive materials.

- Ease of Use: Quick and easy to apply and remove.

6. Cable Lockouts: Versatile and Effective

Cable lockouts are highly versatile devices that can be used to lock out multiple energy sources simultaneously. They consist of a flexible cable and a locking mechanism, making them ideal for complex lockout situations.

Key Features to Consider:

- Length and Flexibility: Sufficient length to wrap around multiple devices.

- Strength: Strong cable material that resists cutting.

- Locking Mechanism: Secure and easy to operate.

7. Group Lock Boxes: Centralized Safety

Group lock boxes allow multiple locks to be applied to a single lockout point. The keys to these locks are then placed inside the lock box, which is secured with a lock for each worker. This method is particularly useful for large-scale maintenance operations involving many employees.

Key Features to Consider:

- Capacity: Enough space to hold multiple keys.

- Durability: Strong, tamper-proof construction.

- Visibility: Clear labeling and bright colors.

Conclusion

Implementing a comprehensive LOTO system involves more than just locks. Utilizing the right accessories, such as high-quality tags, hasps, valve lockouts, circuit breaker lockouts, plug lockouts, cable lockouts, and group lock boxes, can significantly enhance the safety and efficiency of your lockout/tagout procedures. At Lukkosafety.com, we provide top-tier LOTO solutions, including products from the best LOTO tags manufacturer in India, to ensure your workplace remains safe and compliant.

Investing in these essential LOTO accessories not only protects your employees but also ensures that your company meets stringent safety regulations. Explore our range of products today and take the next step in safeguarding your workplace.

For more information and to view our full range of LOTO products, visit Lukkosafety.com.